Civil Engineering and Development Department

As the first of its kind in the world, the Automated Concrete Cube Testing System fully automates the entire process from concrete cube curing to testing, significantly improving OSH by minimising manual handling of repetitive tasks.

The system is equipped with a computer control unit to carry out the entire testing process automatically, including registering and loading concrete cube samples into curing tanks, retrieving samples at specified time, drying cube samples, measuring sample mass and dimensions, conducting compression tests and classifying fracture modes by artificial intelligence (AI).

The system incorporates a range of innovative and advanced technologies, including high-precision robotics, Internet of Things (IoT), AI, and computer vision analysis. It has won multiple awards in both local and international competitions.

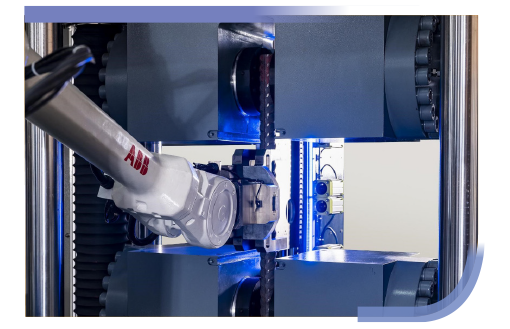

The key advantage of the Automated Steel Rebar Testing System which is the first of its kind in Hong Kong is the integration of an optical extensometer, eliminating the need for human-machine interaction during tensile testing.

In conventional manual operating procedures, laboratory personnel are required to use saws to inscribe equidistant marks on the steel rebar samples and to physically attach a clip-on type extensometer to the steel rebar in order to measure the extension of rebar during the test. These processes expose the operators to various potential hazards. For example, the steel rebar will break suddenly under high tension, the personnel have to be in close proximity to the test specimen and then quickly dismount the extensometer before the rebar breaks to prevent damage to the extensometer. The optical extensometer of the automated system, on the contrary, uses non-contact optical technology to accurately measure in real time the extension (or strain) of the steel rebar without any direct human interaction.

This innovative approach combines robotics and IoT technologies to effectively reduce the risk of injury among the staff, thereby raising overall OSH standards.

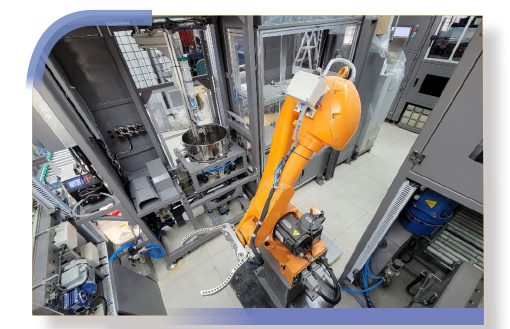

The newly developed Automated Soil Proctor Compaction Testing System is the first of its kind in Hong Kong that completely eliminates manual labour work such as manual handling of heavy soil materials.

Amongst various fill compaction control tests, Proctor Compaction Test is the most repetitive and labour-intensive work, which involves manual handling of heavy fill material (sieving, subdividing, mixing and compaction) and places a significant physical burden on laboratory personnel. Soil samples required for each test can be up to 80 kilograms and the test is usually performed by two to three laboratory personnel. A laboratory operator is required to lift and drop a 4.5-kilogram rammer to compact the soil sample in a mould in five layers, apply 62 blows for each layer and repeat the test five times with different water contents, entailing a total of 1,550 blows for each operation. This exposes the operators to the risk of musculoskeletal injuries, such as back strain or muscle fatigue. The repetitive nature of the compaction testing, which involves the use of heavy rammers, gives rise to safety concerns, as operators are subject to the potential risk of acute injuries. The automated system for Proctor Compaction Test can reduce laborious effort (now involving only one laboratory personnel) and hence improve the OSH of our laboratory personnel.

The system is equipped with a robotic arm, an automatic sieve shaker, an automatic riffle system, an automatic mixer, automatic soil compactors, and a safety laser curtain, thereby ensuring a safer and more efficient testing process. In addition, noisy operations are fully enclosed, further enhancing OSH standards.

Traditional construction materials testing industry in Hong Kong adopts conventional testing methods which involve highly repetitive, physically demanding and labour-intensive manual operations. The laboratory automation initiatives of the PWL have demonstrated the technical applicability of adopting advanced technologies and innovative solutions in replacing manual operations with machine automation. The automated concrete cube testing system, steel rebar testing system and soil compaction testing system developed/adopted by the PWL have showcased the significant enhancement in the efficiency, quality and reliability of the testing services as well as the great improvement to the OSH of laboratory personnel. PWL personnel now work in an environment where the risk of work-related injuries has been substantially reduced (no injuries/ accidents have been reported so far since the implementation of these systems), enabling them to focus on their tasks with heightened awareness and vigilance towards maintaining a safe and productive workplace. The automated systems help assure the quality of construction materials used, which is crucial to the structural stability and service life of the buildings and infrastructures being developed. The successful implementation of these pioneer automation systems not only serves as a showcase of innovative technologies, but also stimulates the modernisation of the construction materials testing industry in Hong Kong and helps fostering the OSH culture.

The three systems have won a number of prestigious awards, including Certificate of Merit of the Hong Kong Institution of Engineers Grand Award 2023 (Industrial Category), Bronze Medal at the 48th International Exhibition of Inventions of Geneva, Gold Medal at the 3rd Asia Exhibition of Innovations and Inventions Hong Kong, and Silver Award of the 23rd Hong Kong Occupational Safety and Health Award (OSH Enhancement Program Award).